|

Ointment

Processing Equipments

|

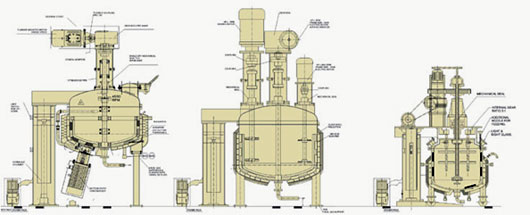

Contra Rotary Mixer |

|

|

The high - flexibility of the here

described mixer allows the production of any paste, creams for

Cosmetics & Pharmaceuticals Industries. This mixer is designed

with high volumes to reduce the production time and increase the

production capacity. The Mixer is based on contra rotating

mixing principle.

The equipment is also available with bottom homogenizer and

re-circulation systems for better uniform mixing.

The capacity ranges from 3 litres to 5000 litres. |

|

| |

|

Vibro Sifters |

|

|

Vibro separators are circular

gyratory screens used to separate solids from solids and liquid

from solid. Vibro Sifter consists of Specially Designed Motor

mounted vertically at the center of the base plate of the

Screen. The Screen is in between feeding hopper and bowl. The

material is fed on to the centre of top screen. The undersize

material passes rapidly through the screen during its travel to

the periphery. The over size material get continuously

discharged through a tangential outlet. This is achieved by

specially designed Vibratory Motor along with eccentric Top and

Bottom Weights. |

|

| |

|

Saima Mixers |

|

|

Stainless steel vacuum Saima mixer

with hydraulic power pack and controls. Vessel design pressure

-1 barg at 150⁰C. CS jacket DP 2.5 barg at 150 ⁰C with volume of

230 litres. Mixer material 1.4301 (304). Unit has a 22 rpm

scraped wall and base agitator driven by a motor, at 970 rpm

disc and dissolver disc and 970 RPM and 2955 rpm for homogeniser

/ distributor unit Central bottom discharge. Unit has hydraulic

lifting unit to lift agitators out of bowl for cleaning. Unit

designed for cream, liquids, ointments and paste mixing.

The Above Mixer ranges from 10 ltrs to 3500 ltrs and is

available in Total GMP model (ctc parts S.S 316 & non ctc parts

S.S 304). |

|

| |

|

Tube Filling Machine |

|

|

Salient features

:-

-

Dripless accurate filling.

-

Filling accuracy ± 1%

-

Filling range 5gm to 500gm

-

Quick change over to different

filling range

-

Totally GMP model

-

Speed depending upon volume &

viscosity of the product

-

All the contact parts are

304/316/316L quality as per your

|

|

Optionally Available :-

- Automatic container feeding

with turn table or packing conveyor

- Jacketed hopper & mixing

stirrer

- Plugging & capping machine.

|

|

| |

|

Liquid Filling Machine |

|

|

Technical Specifications :-

-

Output =700 TO 3000

containers per hour Depending upon volume and viscosity of the

liquid to be filled.

-

Power Supply0.5 HP,

1440 rpm, 440 v, 50 Hz, 3 phase.

-

Filling Range 5 ml

to 1000 ml with suitable change parts.

-

Nozzles = Spring

loaded nozzles.

-

Syringes (Volume

Range) 20 ml to 100 ml OR 50 ml to 250 ml OR 100 ml to 500 ml OR

550 ml to 1000 ml

-

Overall Dimensions

(mm) 400 (w) x 500 (d) x 650 (h).

|

|

| |

|

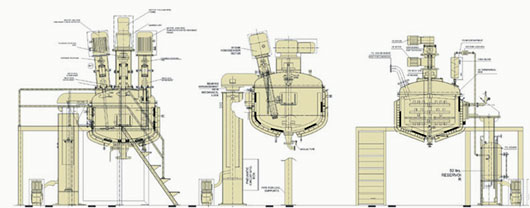

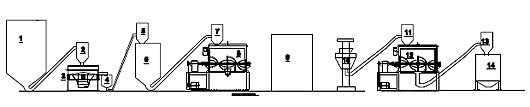

Ointment Plant |

|

|

|

| |

|

Hair Dye Plant |

|

|

|

| |

|

|